The home heating dream team – bringing boilers and heat pumps together to offer the best of both worlds. Hybrid heating is a simple step into new, lower carbon^ technology. And with millions of homes already hybrid ready, we’re ready when you are.

Hello hybrid heating

The home heating dream team – bringing boilers and heat pumps together to offer the best of both worlds.

Hybrid heating is a simple step into new, lower carbon^ technology. And with millions of homes already hybrid ready, we’re ready when you are.

Expand your skills

Our experienced training team will get you up to speed.

Grow your market

Attract new customers and future-proof your business.

Install with confidence

All our hybrid systems are tried, tested and top-notch.

View our Hybrids

Compress 5800i Hybrid Heat Pump

Co-created with installers and built for fast, simple, plug-and-play installation – the compact CS5800i Hybrid Heat Pump brings electrified heating into your customers' homes.

7000i AW Hybrid Heat Pump

Our Hybrid 7000iAW delivers the best of both worlds. It allows the integration of a high efficiency heat pump with the benefits of a gas combi boiler.

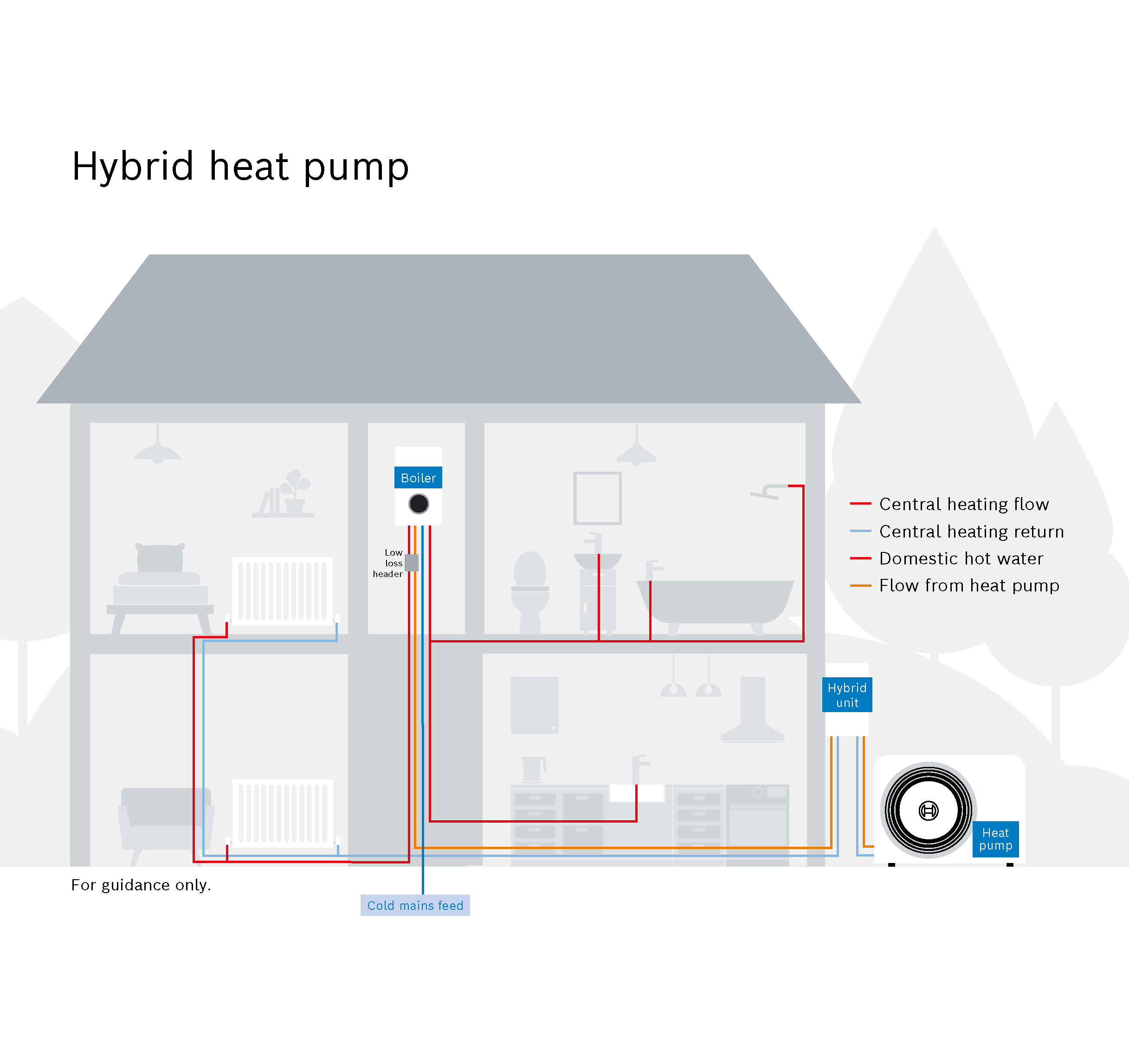

What is a hybrid system?

At a glance, a hybrid heating and hot water system is a combination of two or more technologies generating heat together as an electrified alternative for home heating.

Check out the explainer video below from training’s Mike Siviter.

The future of our industry

With the Government’s target to achieve net zero by 2050, we're here to support you with renewable solutions to futureproof your business.

Discover heat pumps and find out more about the future of heating.

Get technical

Interested in expanding your business or looking to offer your customers an electrfied heating solution?

Book a heat pump or hybrid training session

View our boilers and heat pumps

Boilers made better

View our range of gas and oil boilers.

Feel good heating

Discover our heat pump range.

Meet our Electrified Solutions team

Our Electrified Solutions Team are located up and down the country, making it easy for you to get support from our expert team, wherever you’re based.

FAQs

^A hybrid heat pump system when running emits less carbon dioxide compared to only using a gas or oil boiler.

^A hybrid heat pump system when running emits less carbon dioxide compared to only using a gas or oil boiler.